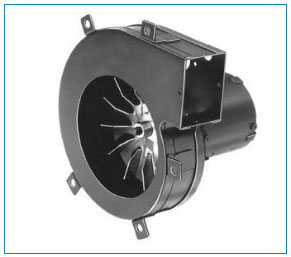

Centrifugal blowers

Centrifugal blowers look more like centrifugal pumps than fans. The impeller is typically gear-driven and rotates as fast as 15,000 rpm. In multi-stage blowers, air is accelerated as it passes through each impeller. In single-stage blower, air does not take many turns, and hence it is more efficient. Centrifugal blowers typically operate against pressures of 0.35 to 0.70 kg/cm2, but can achieve higher pressures.

- Highly efficient blower with a state of the art impeller design and improved belt design with less friction

- Longer service life, with the blower design using minimum belt tension for all pulley ratios

- Low maintenance due to long lasting belts, unique belt tensioning systems, and patented filter design

- Quiet operation: advanced engineering and precision manufacturing reduce the vibration & noise of our centrifugal blowers

Centrifugal Blowers making use of External Rotor Motors have wide applications in UPS, Control Panel, Railways, Rectifier, Blow Molding machines etc. Centrifugal Blower has high efficiency and low noise level, relatively small airflow with high static pressure. It is a space saving blower. These Centrifugal Blowers are available in either single or dual inlet. The single inlet external rotor motor is integrated in the impeller, which is mounted onto the side wall of the scroll housing. Dual Inlet Blowers have extremely low structured vibration rates.